With over fifteen years manufacturing experience, Breed Media has established a reputation for reliable, high quality vinyl record pressing. We provide a wide range of UK vinyl record pressing and printing services, including record cutting, coloured vinyl, bespoke special vinyl options, test pressings plus double and tripple vinyl in gatefold sleeves. From a simple 7" record in a printed sleeve or 12" vinyl in a black disco bag through to custom vinyl print packaging options we deliver knowledge and service everytime.

12 inch vinyl pressing

Create quality 12 inch vinyl pressings with Breed UK. Our team will apply their expert knowledge of vinyl mastering, record cutting, printing and packaging to your vinyl record manufacture to get the best from your music and artwork. Our bespoke 12 inch vinyl options include heavyweight and colour vinyl, disco bags, printed sleeves and special packaging to elevate your next release.

12" Vinyl Pressing

10 inch vinyl pressing

Stand out from the crowd with a 10 inch vinyl pressing including coloured vinyl, gatefold sleeves and bespoke printing finishes such as embossing and hot-foiling. We can guide you through mastering, vinyl cutting and sleeve design to create a unique premium bespoke vinyl record.

10" Vinyl Pressing

7 inch vinyl pressing

Choose a classic black 7" vinyl record pressing in printed sleeve for your next single release. We provide options for etched vinyl, coloured vinyl, gatefold sleeves and bespoke printing finishes such as embossing and hot-foiling. Let the Breed team guide you through mastering, vinyl cutting and sleeve design to create a premium release.

7" Vinyl Pressing

Gatefold Sleeve Vinyl

We have double and triple gatefold sleeve options for 7 inch, 10 inch or 12 inch vinyl records. Our gatefold vinyl sleeves are perfect for double or triple vinyl albums and can accommodate extras like posters and lyric sheets. For single vinyl releases we make sure our gatefold sleeves have left panel glueing for a quality finish.

Gatefold Sleeve Vinyl

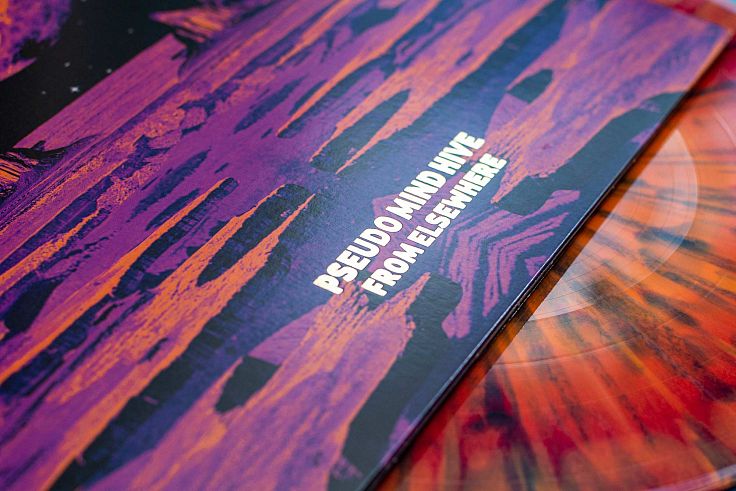

Coloured Vinyl

Our carefully crafted colour vinyl pressings will help you realise your artistic vision. Explore different inner sleeve options such as black paper, poly-lined paper or custom printed inner sleeves. Outer sleeves with 3mm, 5mm, or 7mm spines can be manufactured, tailored to your individual release. Pantone colour printing (according to their latest colour chart) and further creative finishes such as embossing, hot-foiling and bespoke die-cutting are also available. Our vinyl is produced with luxury lithographic printing and sustainably sourced inks.

Coloured Vinyl Pressing

Special vinyl

Unlock your vinyl potential with our special vinyl pressing service. Our comprehensive package includes expert artwork analysis, proofs, and printing plates, meaning you’ll experience the ultimate sound and print quality. We offer special, bespoke vinyl options, ranging from heavyweight vinyl, splatter vinyl, colour in colour, and half and half variations. Once you’ve chosen your product, our custom packaging service provides shrink-wrapping as well as eco-alternatives for a truly tailored experience.

Special VinylVinyl FAQs and Info

Vinyl records are pressed in a three stage process which starts with cutting a lacquer or DMM from which stampers are made to actually press the record. Find our more in our article on How are Vinyl Records Made.

Your audio masters for vinyl pressing can be supplied as zipped WAV files via our ftp upload site (contact us for details), by wetransfer, dropbox or via CD-R/retail-ready CD—along with a full tracklist, timings and side splits.

The standard bit rate to press vinyl is 24 bit/44.1KHz. The master should be fully edited and as you want it to sound, with all tracks in the correct order and with your desired gaps between each track.

A complete track list should be supplied with every record pressing master. The list should contain the names of all the tracks, each track’s duration and the side splits for correct separation into side A and side B. These are mandatory requirements.

The quality of vinyl audio is directly affected by the distance between the record grooves and therefore the playing time of the record. Exceeding the maximum recommended playing lengths below can compromise the audio quality of the record, with bass heavy recordings particularly problematic.

At 33 rpm:

- 12" - 19 mins per side

- 10" - 14 mins per side

At 45 rpm:

- 7" - 5 mins per side

- 10" - 10 mins per side

- 12" - 15 mins per side

When pressing vinyl with hidden tracks or any unusual features this should be clearly communicated to us at the ordering stage. Provide the track number, name, time and details of your special requirements. Examples include long gaps between tracks, very quiet passages or deliberate use of electronic buzz or distortion etc.

Once your vinyl record masters and order are received, we cut the audio to either lacquer or direct to copper plates (DMM) depending on various factors. Both lacquers and DMMs are created on a special lathe which looks like a large record player and works rather like a record player's phonograph pick-up in reverse, where the audio is converted to mechanical motion. The cutting stylus, mounted in the head, cuts a precise spiral groove across the plate spinning at an exact speed of 331/3 or 45rpm, and vibrates to transfer the recording. Once the cut has taken place, lacquers are processed, firstly to a negative using nickel and an electroplating process, then again to create a positive. These are then plated once more to form the stampers (negatives again), which are then used to press the final records. DMM Coppers are processed directly to stampers.

TPs are supplied for you to check that the A and B sides are correct and the music is in the right order. It is too late to change levels and EQ at this stage. Breed Media is unable to further your order until you have approved your test pressings.

Your records are hand-packed, but on oassion some vinyl record pressing plants pack directly into a ‘bag' (a sleeve without a spine). Therefore, most record manufacturing runs will include a hand-packing charge. Stickers and inserts are normally hand-packed too. We require an accurate description of the required sticker position. You should always consider where any shop placed pricing stickers may appear (usually top right). Hand-packing is charged per movement.

Colour vinyl record pressing is undertaken using different material to solid black vinyl which crucially doesn't contain graphite. As a result the quality the quality of sound may vary, in particular, higher noise levels and isolated static sounds (clicks) may appear in the lead-in and run-out grooves, in the track crossovers and at any quiet points of the recording. For more information see our Coloured Vinyl Page

Order Vinyl

To order your vinyl go to vinyl prices where you can quickly select a package, get a price and send us your order.

If you prefer just contact us to get started on your next vinyl pressing project.

Who We Are

At Breed Media we're here to support musicians and bands at every stage of their journey. From new bands to established artists we're here to demystify the process of manufacturing your record and make it as straight forward as possible so you can concentrate on the creative process of producing music and packaging ideas.

We believe in the ‘Triple Bottom Line’ principle, pursuing social equity, environmental quality, and economic prosperity. With a focus on active environmental care, responsible trading practices and equitable employment so you can rely on us to keep your products as sustainable as possible.

Join us in making a difference through engaging physical media products that hold deep meaning and resonate with your audience. Express yourself, support sustainability and evolve with us at Breed Media.